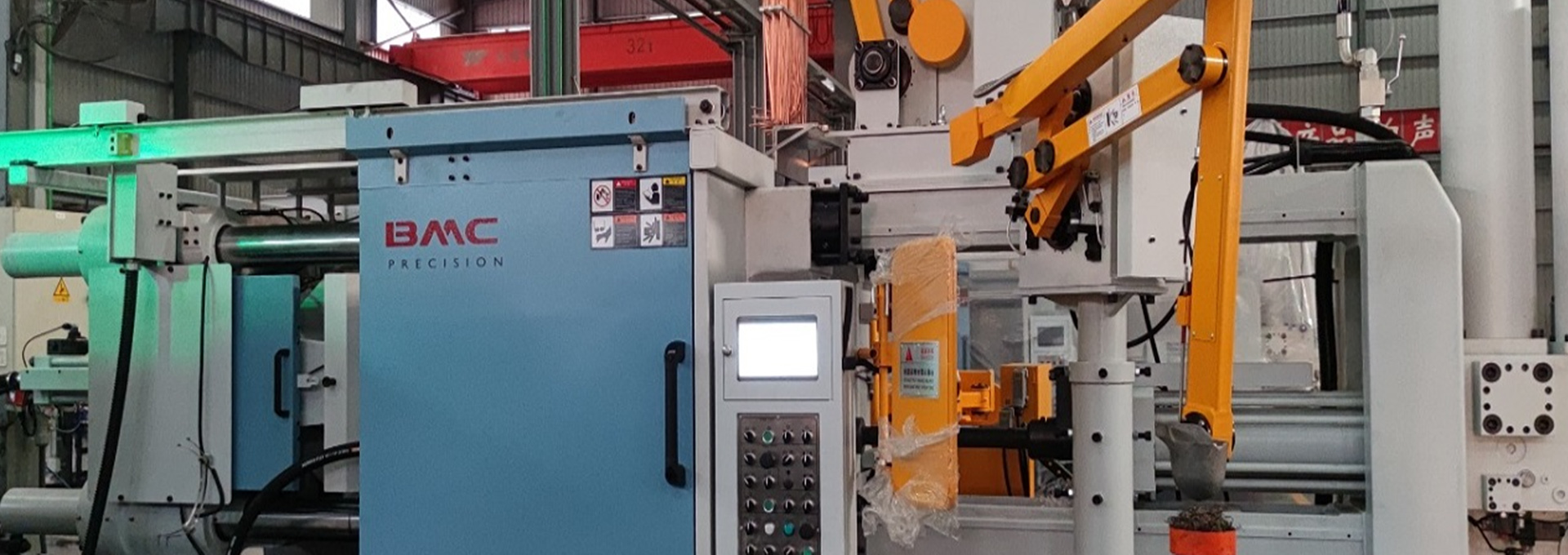

CASTING THROUGH HPDC / GDC

- A Total of 6 nos. of a wide range of Die Casting machines (2 HPDC Machines in Peenya Unit 1 and 3 HPDC, Machines in Dabaspet Unit 2

- Capacity to produce castings in the weight range of approx.. 20 grams to 3.5 kilograms.

- Installed Capacity is approx.. 10,000 Tons of Castings per annum (7,000 Tons @ Unit1 & 3,000 Tons @ Unit 2)

- Present production is around approx.. 100 Tons per annum (Approx. 50 Tons @ Unit 1 & 50 Tons @ Unit 2)

- Various Casting technologies like Vacuum, Squeeze Pin, Mould temperature Control, Jet Cooling, etc are used extensively in the Casting Production Process.

| MACHINE SIZE | 100 TON | 150 TON | 250 TON | 350 TON | 430 TON | 460 TON |

|---|---|---|---|---|---|---|

| AT UNIT 1 | 0 | 0 | 0 | 0 | 1 | 1 |

| AT UNIT 2 | 0 | 3 | 1 | 0 | 0 | 0 |

| Total | 0 | 3 | 1 | 2 | 1 | 1 |

MELTING

High efficiency tower melters are used for melting Aluminium Ingots. Degassing & filtration are performed to ensure the best quality Molten Aluminium is delivered to the Die Casting machines. Further quality check like K-Mould and dissolved gas content are also done before transfer of Metal.

CNC MACHINING

Our in house CNC Machining facility gives RISE DYE CASTING the advantage of being a “One Stop Shop” for Customers.

The CNC Machining section is equipped with a battery of 8+ CNC machines, consisting of a wide variety of machines including VMC’s / Turning Centers / TMC’s / Twin Spindle Turning Centers and VMC’s, enabling Chamundi to supply fully Finished Machined Components to its customers. All VMC’s are equipped with 4th axis machining capability. Some VMC’s are also equipped with 5th axis machining capability.

| MACHINE SIZE | 100 TON |

|---|---|

| SINGLE SPINDLE TURNING CENTER | 7 |

| SINGLE SPINDLE VMC | 1 |

| TURNING CENTER | 8 |

TOOL ROOM

A tool room is a specialized facility equipped with advanced machinery and technology for the design, development, and manufacture of precision tools, dies, moulds, jigs, fixtures, gauges, and related components. These facilities support industries, particularly small and medium enterprises (SMEs), by providing precision tooling services, skilled manpower training, and technical consultancy.

SUB ASSEMBLIES

Simple, Sub Assembly Operations, like Rubber Bush and Sleeve fitting, Steel ball pressing, dowel pin, etc. are also undertaken in order to supply customers with Direct On Line Products making RISE DYE CASTING a First Choice Supplier for many a customer.